Technical Bulletin DVS 3410 (02/2019)

Self-pierce Riveting – Overview

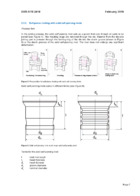

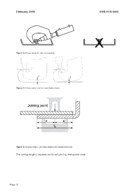

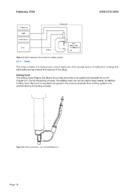

This guideline provides users of the joining process "self-pierce riveting with semi-tubular and solid self-pierce rivet" with an overview and information on the technology, the design of components, suitable materials and their quality assurance. In self-pierce riveting, overlapping parts are joined without pre-piercing using solid or semi-tubular self-pierce rivets (hereinafter also referred to as joining elements). The mechanism of action is based on a combination of force and form locking. In self-pierce riveting with half-hollow pierce rivet, the joining element is pressed through the punch-side joining part (the punch-side joining parts in the case of multilayer joints) in an uninterrupted joining process and the die-side joining part is formed with the aid of the rivet and die geometry.

Published

All topics

- Joining in road vehicle construction

- Joining in electronics and precision engineering

- Welding in boiler, tank and pipeline construction

- Welding in building trade

- Weldig in skilled trades

- Welding in aircraft and spacecraft construction

- Welding in rail vehicle construction

- Welding in shipbuilding and marine technology

- Welding in turbo engineering

- Additive manufacturing

- Electron beam welding

- Gas welding

- Brazing

- Adhesive bonding technology

- Laser beam welding and allied processes

- Arc welding

- Mechanical joining

- Friction welding

- Cutting technology

- Thermal spraying and thermally sprayed coatings

- Ultra-short pulse laser

- Underwater welding and cutting

- Soft soldering

- Resistance welding